|

Ningbo Nide Mechanical Equipment Co., Ltd.

|

China Automatic motor armature coil winding machine armature winder manufacturer

| Price: | 10000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The automatic armature winding machine is designed for winding motor armature used in home appliances, power tools and automobile motor industry.

Automatic armature winding machine / flyer winding machine for sale

NIDE produces and manufactures a variety of motor winding machines, including armature winding machines, stator winding machines, brushless / BLDC winding machines, coil winding machines, needle winding machines, etc.

This automatic armature winding machine is simple to operate and designed for the various armature sizes. It adopts the high efficient industrial automation technology, increases production efficiency and saves labor coat for motor manufacturers. The armature winding machine is suitable not only for individual winding automatically, but also for batch automatically winding of armatures.

Armature winding machine Application:

The automatic armature winding machine is used in automatically winding hook type commutator armature or armatures with tilted slots.

And it is designed for winding various types of medium and big wire diameter motor armature used in home appliances, power tools and automobile motor industry , DC motor , etc.

Armature winding machine Function and Feature:

1.The armature winding machine is a universal machine for winding a diverse range of armatures coils , and is facilitate automatic wire hooking, cutting, and indexing.

2.The armature coil winder is suitable not only for individual winding, but also for batch winding of armatures.

3.According to the armature diameter and the rotor stack length , the copper wire guiding device is simple and quick to set.

4.100 memory parameter setting for different type armature

5.The counter can be switched for both, forward and reverse winding.

6. Cylinder automatically convey armature.

7.It is easy and fast fixture and mold changing. Tooling change time is around 5 minutes.

8.After the pre-set number of turns has been reached, the winding machine stops automatically.

9.The armature winding machine can be stopped during the winding cycle by means of a lever stop switch.

10.Password setting can avoid the type setting change easily.

11.The high effective industrial automation technology

12.I/O test can be done from touch screen,

13.Different winding turn in each slot and hooking change can be set.

14.The whole process is displayed dynamically and with sound-light alarm function.

15.Operator can handle several machines at same time which increasing production efficiency and saving labor cost.

Armature winding machine Main Configuration:

1.Aluminium Alloy cover

2.Imported organic glass

3.Much stronger structure.

4.Stable, sway-proof fixture and wire protection system,

5.Adapts 3 sets AC servo motor to control winding and angle.

6.User computer interface is with touch menu, user could edit, modify, save the data, and password control also available.

Armature winding machine Technical Parameter:

Product name : | automatic motor armature rotor winding machine |

Wire diameter range: | 0.16~1.2 mm |

Armature diameter: | 20~60 mm |

Stack length: | 10~70 mm |

Shaft diameter: | 3~15 mm |

Shaft length: | less than 250mm |

Armature Slot: | even slot |

Turn number: | 0~9999 |

Commutator diameter: | 8~40 mm |

Winding speed: | 0~2500 rpm |

Winding motor power: | 1.5KW X 2 |

Angle detecting speed: | 0~3000 rpm |

Angle detecting motor power: | 0.75KW X 1 |

Air supply pressure: | 4~6 Kg/cm2 |

Total power: | 4.0 KW |

Voltage: | three phase AC 380V 50/60 Hz |

Dimension: | 2000(length)X1000(width)X1800(height)mm |

Weight: | 1250 Kg |

Armature winding machine Productivity:

For example: for a 12 slot, 0.38mm wire diameter, 24 bar commutator armature. It only takes 22 seconds/pc

How to operate the armature winding machine

1.Put the armature in the chuck mechanism manually.

2.Press the start button,the cylinder push the armature to the right position automatically.

3.The machine starts to coil winding automatically,

4.Take the winding completed armature out by hand.

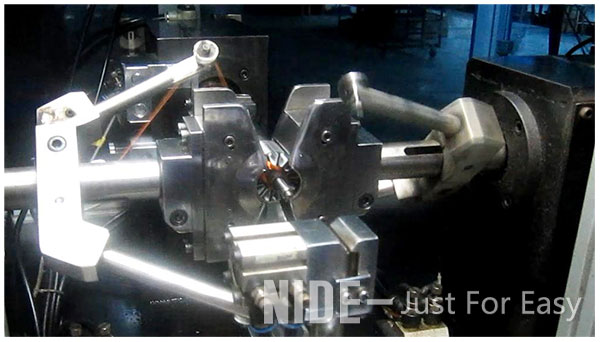

Armature winding machine Picture:

1.motor armature show after coil winding

2.The motor winding machine working process show

.jpg)