|

Ningbo Nide Mechanical Equipment Co., Ltd.

|

Automatic Armature coil winding machine

| Price: | 10000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

| View the Video: |

|

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Wire diameter range: ¢0.19~¢0.65mm

2.Armature diameter: ¢20~¢60 mm

3.Armature stack length: 10~60 mm

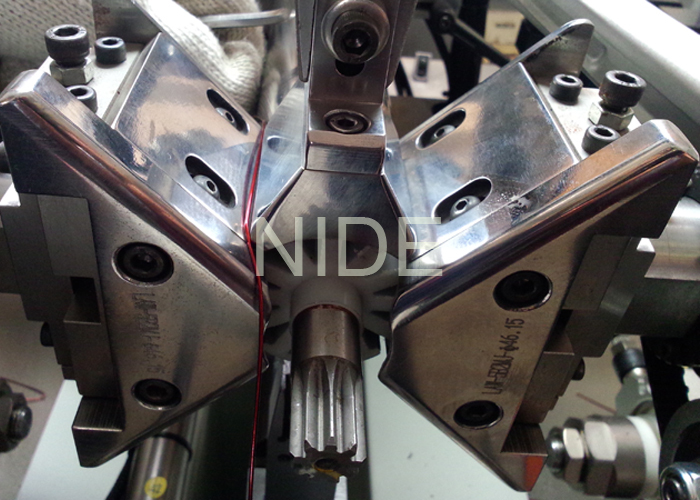

ND-LAW-5A1-C Automatic Armature Winding Machine

Main technical data:

| Wire diameter range: | ¢0.25~¢1.0mm |

| Armature diameter: | ¢20~¢60 mm |

| Armature stack length: | 10~60 mm |

| Armature slot number: | odd or even slot |

| Shaft length: | 50~ 250mm |

| Turn number: | 0~99999 |

| Commutator diameter: | ¢18~¢40 mm |

| Winding speed: | 0~3000 rpm |

| Indexing speed: | 0~3000 rpm |

| Action: | single action or automatic |

| Production efficiency: | 600pcs/8hours(based on armature with 12slots 24hooks, 20turns) |

| Air supply pressure: | 4~6 Kg/cm2 |

| The machine total power: | 4.0 KW |

| Voltage: | three phase AC380V±10%, 50/60 Hz |

| Weight: | about 1180 Kg |

Feature:

Three winding mode: single slot-single hook, single slot-double hook and double layer winding. It could do twice winding in one slot, four times winding in the two adjacent slots.

It could select to wind single or twice, set to wind on the journal of the armature, slow rise and slow decline function, stable type fixture, up-down protective module, protective hooking.

Only can snap break the wire: winding before break the wire, or break before winding.

Production parameter for 100nos armatures could be stored

Display parameter, including shift output, total output, consuming time, present slot No. turn No. and hook No., etc.

Automatic alarm if any abnormal condition occurs: alarm on the touch screen, buzz alarm and light tower alarm.

Manually put the armature onto the winding station.

Main Configuration:

Indexing servo motor: 750W*1 spindle: Mitsubishi

Winding servo motor 1000W*2 spindle: Mitsubishi

PLC: Mitsubishi FX3G/FX1N

Extension module: Mitsubishi

Relay: Omron

Proximity switch: AUTONICS, Omron or Shenshi

Touch screen: 7", WEINVIEW

Air switch: MITSUBISHI

Transformer: Changzhou Huatong, three phase 400V, single phase 230V

Combined power source: NIDE

Circuit breaker: DELIXI

Indicator and button: SCHNEIDER

Button box: SCHNEIDER

Operation box: sheet plate

Automatic safety door: Not available

Ball bearing: UBC or NSK

Transmission linear guide: ABBA or HIWIN or TBI

Automatic scissor: Not available

Winding top transmission base: nodular cast iron

Winding bottom transmission plate: steel plate

Winding flier: die-casting aluminium alloy, integral type, double shaft balancing calibration, easy disassemble, standard type

Winding spindle: standard short spindle

Winding fixture: Cr12 integral quenching, HRC60

Indexing transmission base: nodular cast iron

Indexing spindle: standard model 22-14(OD22mm, ID14mm)

Operation plate: cast iron, 1260(L)x 945mm(W)x80mm(Thickness), natural aging more than two years.

Buffer: AIRTAC

Cylinder: AIRTAC

Pressure reducing valve: AIRTAC

Air source treatment elements: SMC

Electromagnetic valve: SMC

Semi-auto loading structure: AIRTAC cylinder + linear bearing + guide shaft. Manually put armature onto the winding station, manually remove the wound armature from the winding station.

Tensioner: MITSUBISHI electric magnetic powder tensioner (wire diameter range: ¢0.2~¢0.65mm)

Or WANNER (Switzerland brand)/Hangzhou Puwei magnetic tensioner(wire diameter range: ¢0.19~¢0.45mm)

Or Dongwan Zhangli Hysteresis electronic tensioner(wire diameter range: ¢0.19~¢0.25mm)

Rotor winding Machine detailed picture

Armature winding by this rotor winding machine

Armature winding by this rotor winding machine

Double palm "start" button.