|

Ningbo Nide Mechanical Equipment Co., Ltd.

|

Automatic armature wire winding machine

| Price: | 10000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

This armature winding machine is used for automatically hook type commutator armature winding, it is suitable for winding medium and big wire diamet

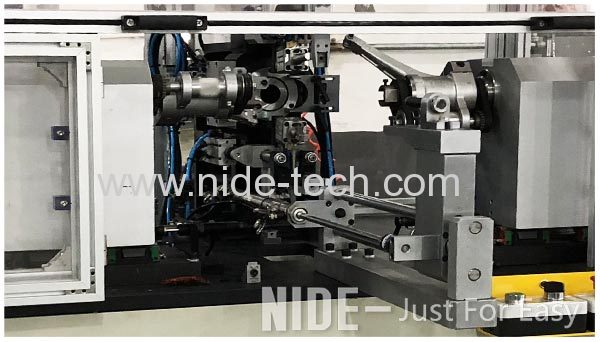

Automatic armature motor rotor coil winding machine

This armature winding machine is used for automatically hook type commutator armature winding, it is suitable for winding medium and big wire diameter armature. Automatic feeding, winding,indexing and wire cutting, only load and unload armature from material loader. Equipped with touch screen and PLC, winding parameter could be set and modified on the screen. We also have armature winding machine equipped with conveyor, operator only need to put several pieces of armature on the conveyor at one time, then machine will finish all the armatures automatically. Below parameter is our standard machine, we could produce machine according to customer's armature accordingly.

(1) Application

The motor armture winding machine is suitable for home appliance, car and power tool motor aramture.

(2) Technical Parameter:

| Item | Specification |

| Armature O.D range: | 20~60mm |

| Armature slot: | Even slot |

| Commutator diameter: | 18~40mm |

| Wire diameter: | Magnetic hysteresis method: 0.16~0.55mm/ Electric control method: 0.30~0.85mm |

| Stack length: | 10~60mm |

| Shaft diameter: | 3~17mm |

| Shaft length: | Less than 300mm |

| Turn number: | 0~9999 |

| Winding speed: | 0~3000rpm |

| Winding motor power: | 1.5KW* 2 |

| Angle detecting speed: | 0~3000rpm |

| Angle detecting motor power: | 0.75KW*1 |

| Air supply pressure: | 4~6Kg/cm2 |

| The machine total power: | 4.0KW |

| Voltage: | Three phase AC380V50/60Hz |

| Dimension: | 2000(length)X1300(width)X1800(height)mm |

| Weight: | 1200Kg |

(3) Production efficiency of this machine

Around 1000pcs/8 hours,it is only a rough idea, depends on the armature slots number and turn number.

(4) The operation steps of this machine

Load armature on the shuttle manually, press START button,shuttle will deliver the armature to the winding position, and automatic winding, indexing and wire cutting,after completing, the shuttle will take out the finished armature from winding position, operator unload the finished armature, one cycle is completed.

(5) The rotor winding maching picture show

.jpg)