|

Ningbo Nide Mechanical Equipment Co., Ltd.

|

MIXER MEAT GRINDER MOTOR STATOR COIL WINDING POWDER COATING MACHINE

| Price: | 10000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Application: Motor stator coil powder coating

2.Stator coil material: Enameled wire

3.Stator OD: < Φ95 mm

Stator lamination thickness: <100mm

This Stator Coil Powder Coating Machine is used for stator coil powder coating insulation. This machine has counting function. Working hours can be decided by customer. Machine working ability 120~180pcs/h

1. Design and produce principle

No | Name | Design parameter | Remark |

1 | Workpiece name | Motor stator coil | |

2 | Workpiece material | Enameled wire | |

3 | Workpiece Dimension | Stator lamination diameter<Φ95mm | |

4 | Workpiece weight | <3 Kg Max/pc | |

5 | Output | 120~180pcs/h | This output means the machine working ability; |

6 | Working hours | Decide by customer |

2. Working process:

(1). Load the coil (1pc) to the sling fitting and insert each wire head(heated) into the connection groove,compact inching cylinder.

(2). Turn on the switch (go up and down, heating, coating etc controlled by time relay to work automatically)

(3). After finish coating (the powder adhere to the stator coil and through melting and leveling preliminary, there's a little powder in the inside and outside of the stator lamination, but not melt, it can cleancompletely by preliminary air blowing and subsequent cleaning).Take it down and transmit toanother person,clean the inside and outside of the stator with air blowing gun in the powder cleaning entrance,then put it on the shelf (prepared by customer) for natural cooling → put into oven together for baking[(prepared by customer, the bake requirement of the powder in the oven is the oven temperature rise to the needed temperature for curing powder(this depend on the enameled wire heat-resisting temperature and powder curing requirement), keep hot insulation for over 40 minutes).

3.Machine compositions;

XQTF—10 Coil powder coating machine:1set ,including:

1.1.Machine mainframe 1set

Outline dimension:L1253×W1300(include powder cleaning room 500mm) xH2100mm

The room body manufactured by 1.2mm A3 cold rolled plate.

1.2 .DC electrical heating device: 1set

Heating power(0~10KW,clearance working way)adjustable,it can set heating time.

1.3 .Pneumatic rise and decline device 1 set

1.4 .Fluidized bed coating device: 1set

All PVC plate manufacture, with detachable air chamber and micro-hole sheet.

1.5 .Powder vibration device 1set

1.6. First step pulse recycling in the back 1set, with 2pcs filter element and pulse auto back flushingfunction, it can clean the powder in the filter element automatically without turning off the machine, with 1 set powder-blowing gun.

1.7. The coating room doorway install photo-electricity protection(raster)device,this keep the user saver when operating.

1.8 The machine has count function.

(1). Powder secondary recycling machine(outline dimension L830×W830×H1700mm): 1 set

(2). Use 25 type pulse back flushing filter element way recycling machine, motor power 2.2KW.

4. Machine energy consumption index

No | Machine name | Quantity | Electrical(KW) | compressed air (m3/min) |

1 | Powder coating machine | 1 | 10 | 0.3 |

2 | Powder recycling machine | 1 | 2.2 | 0.1 |

Total | 8.2 (Average~KW) | 0.4 | ||

Electric requirement:

(1). Electricity: 380V±10%, 50HZ. Electricity supply way: three phase four wire system.

(2). Compressed air: 0.6Mpa containing oil:≤0.1ppm containing water: ≤ 1.3g/m3

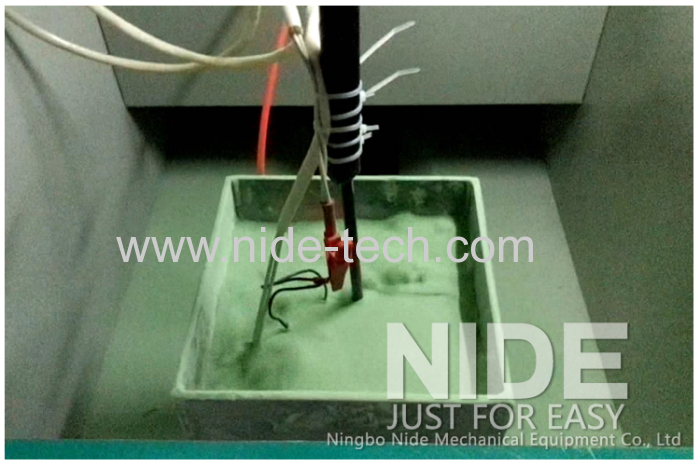

Stator after doing powder coating by this coil powder coating machine

Stator after doing powder coating by this coil powder coating machine

.jpg)