|

Ningbo Nide Mechanical Equipment Co., Ltd.

|

Gold Index: 56391

You are here: home > Motor Information > Application of BLDC brushless motor Winding Machine in Water Pump Motor

Product (535)

- Non-standard intelligent assembly line (3)

- Shaft manufacturing machine (6)

- BLDC motor stator winding machine (29)

- Armature winding line (144)

- stator winding line (221)

- Motor Components (130)

- Technical consulting and turn-key service (2)

Coil winding machine FAQ (5)

Motor Information (9)

Nide Profile (5)

Nide Certificates (14)

Nide factory show (2)

Nide product application (13)

Nide staff show (8)

News (30)

FAQ (29)

After-sales service (1)

Credit Report

Products Index

Motor Information

Application of BLDC brushless motor Winding Machine in Water Pump Motor

Brushless motor can be divided into two points in the application of pump motor

1. Brushless motor type DC water pump:

The motor type brushless DC water pump is composed of a brushless DC motor and an impeller. The shaft of the motor is connected with the impeller, and there is a gap between the BLDC stator and the rotor of the water pump. When the water is used for a long time, the water will penetrate into the motor and increase the possibility of the motor burning out.

Advantages:

Brushless DC motors have been standardized, and there are a large number of specialized manufacturers, which are relatively low in cost and high in efficiency.

2. Brushless DC magnetic drive pump:

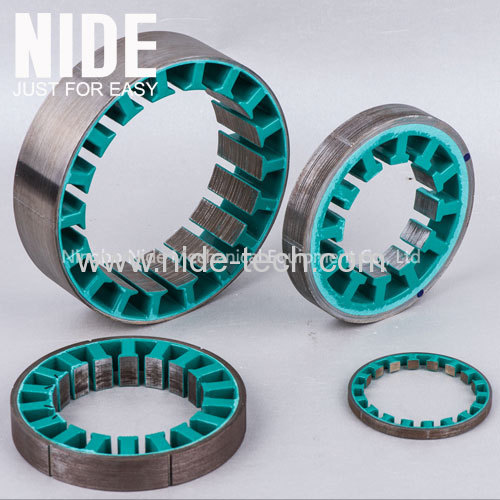

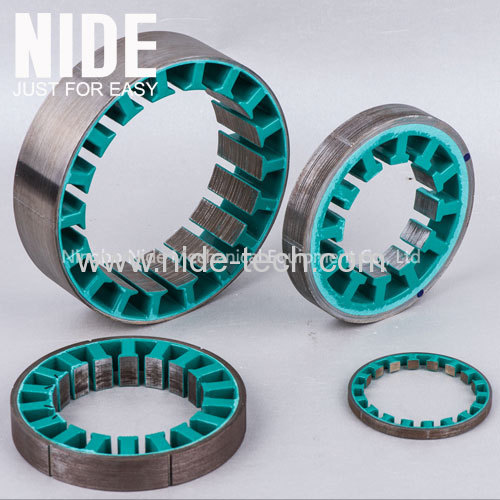

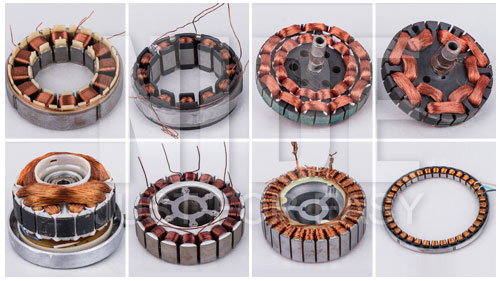

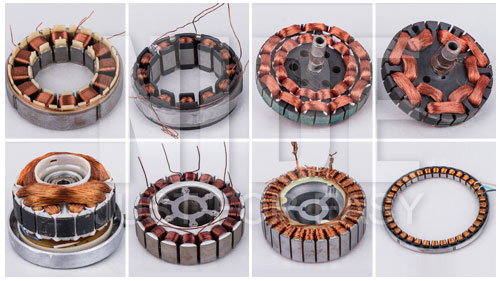

The brushless DC water pump adopts electronic component reversing, no need to use carbon brush reversing, and adopts high-performance wear-resistant ceramic shaft and ceramic bushing. The bushing is integrated with the magnet through injection molding to avoid wear, so the brushless DC magnetic force The life of the pump has been greatly enhanced. The stator part and the rotor part of the magnetically isolated water pump are completely isolated. The stator and circuit board parts are sealed with epoxy resin, 100% waterproof, the rotor part is made of permanent magnet, the pump body is made of environmentally friendly materials, low noise, small size, performance. stable. Various required parameters can be adjusted by winding the stator and can be operated at a wide voltage.

Advantages: long life, low noise up to 35dB, can be used for hot water circulation. The BLDC stator and circuit board parts of the motor are encapsulated with epoxy resin and completely isolated from the rotor. They can be installed underwater and completely waterproof. The shaft of the pump is made of high-performance ceramic shaft with high precision and good shock resistance.

NIDE is Focus on BLDC motor manufacturing solution , including the stone along machine and fully automatic complete line.

Pre Page:

How to distinguish between ordinary...

Next Page:

The difference between ordinary motor...