|

Ningbo Nide Mechanical Equipment Co., Ltd.

|

Gold Index: 56391

You are here: home > Motor Information > The difference between ordinary motor and variable frequency motor

Product (535)

- Non-standard intelligent assembly line (3)

- Shaft manufacturing machine (6)

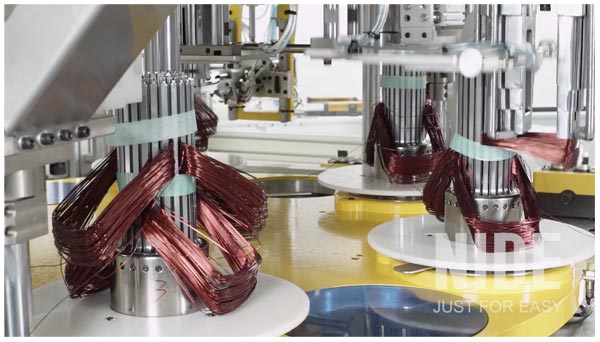

- BLDC motor stator winding machine (29)

- Armature winding line (144)

- stator winding line (221)

- Motor Components (130)

- Technical consulting and turn-key service (2)

Coil winding machine FAQ (5)

Motor Information (9)

Nide Profile (5)

Nide Certificates (14)

Nide factory show (2)

Nide product application (13)

Nide staff show (8)

News (30)

FAQ (29)

After-sales service (1)

Credit Report

Products Index

Motor Information

The difference between ordinary motor and variable frequency motor

1 . Ordinary motors cannot be used as variable frequency motors.

Ordinary motors are designed according to constant frequency and constant voltage, and it is impossible to fully adapt to the requirements of frequency converter speed regulation, so it is not possible to use more variable frequency motors.

2. The influence of the inverter on the motor is mainly in the efficiency and temperature rise of the motor.

The inverter can generate different levels of harmonic voltage and current during operation, so that the motor runs under non-sinusoidal voltage and current. The higher harmonics inside will cause the stator copper loss, rotor copper loss, iron loss and additional loss of the motor. The most notable is the copper loss of the rotor. These losses will cause additional heating of the motor, reduce efficiency, reduce output power, and generally increase the temperature rise of ordinary motors by 10%-20%.

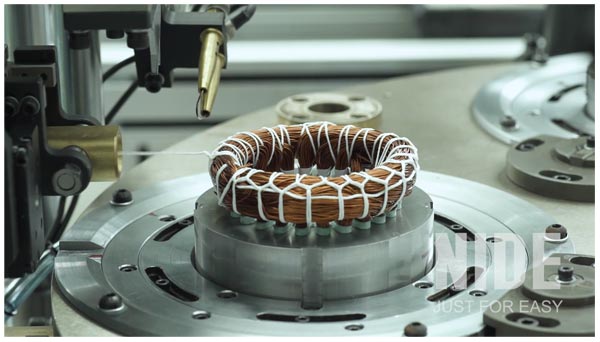

3. The insulation strength of the motor

The carrier frequency of the inverter is from several thousand to ten kilohertz, which makes the stator winding of the motor withstand a high voltage rise rate, which is equivalent to applying a steep shock voltage to the motor, which makes the inter-turn insulation of the motor bear a serious test. .

4. Harmonic electromagnetic noise and vibration

When the ordinary motor is powered by the inverter, the vibration and noise caused by electromagnetic, mechanical, ventilation and other factors will become more complicated. The harmonics contained in the variable frequency power supply interfere with the inherent spatial harmonics of the electromagnetic part of the motor to form various electromagnetic exciting forces, thereby increasing noise. Since the operating frequency range of the motor is wide and the range of the rotational speed is large, the frequencies of various electromagnetic force waves are difficult to avoid the natural vibration frequency of each structural member of the motor.

5. The cooling problem at low speed

When the power frequency is low, the loss caused by the higher harmonics in the power supply is larger; when the speed of the modified motor decreases, the cooling air volume decreases in proportion to the cube of the rotational speed, so that the heat of the motor does not dissipate and the temperature rises sharply. Increased, it is difficult to achieve constant torque output.

Pre Page:

Application of BLDC brushless motor...

Next Page:

How to deal with motor failure