|

Ningbo Nide Mechanical Equipment Co., Ltd.

|

Gold Index: 56391

You are here: home > Motor Information > Automatic motor coil Winding machine

Product (535)

- Non-standard intelligent assembly line (3)

- Shaft manufacturing machine (6)

- BLDC motor stator winding machine (29)

- Armature winding line (144)

- stator winding line (221)

- Motor Components (130)

- Technical consulting and turn-key service (2)

Coil winding machine FAQ (5)

Motor Information (9)

Nide Profile (5)

Nide Certificates (14)

Nide factory show (2)

Nide product application (13)

Nide staff show (8)

News (30)

FAQ (29)

After-sales service (1)

Credit Report

Products Index

Motor Information

Automatic motor coil Winding machine

With the continuous advancement of science and technology, motor winding machines are widely used all over the world. From the original manual cable to the current automatic cable function, the production efficiency of the enterprise has been greatly improved, and the company has achieved better benefits. The continuous development of motor winding technology has made the function of the winding machine more and more powerful. From the traditional manual tapping and shaping to the automatic cable routing, the coil winding process of the motor stator and the motor rotor becomes more simple and efficient. Great progress has also been made.

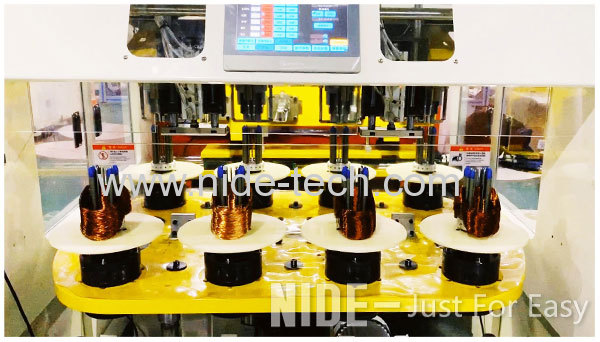

The fully automatic motor stator and rotor winding machine equipment produced by Nide Mechanical can automatically wire, wrap, break the wire, twist the wire, and load and unload. Operators only need to ensure sufficient raw materials, and timely replacement in the absence of workpieces or copper wire to ensure continuous production, in order to achieve high efficiency production. A highly automated machine can meet the requirements of one employee operating multiple devices at the same time.

We often see that the coil resistance values of the same winding machine are different. What is the reason?

Let's take a detailed analysis below:

1. If the number of winding turns is correct, if the percentage of the tolerance is large, there may be material problems, such as different batches of copper wire.

2. If the percentage of the tolerance is not very large, it may be that the degree of tightness of the motor winding machine is different, resulting in different total lengths of the wires, resulting in excessive resistance. The tension of the motor winding machine tensioner is different, and different coil resistances are also presented.

Nide Mechanical automatic motor winding machine can solve the above problems, only need to manually take the coil.

Next Page:

How to make a ceiling fan motor stator?