|

Ningbo Nide Mechanical Equipment Co., Ltd.

|

Gold Index: 56391

You are here: home > Motor Information > The difference between low inertia and high inertia of servo motors

Product (535)

- Non-standard intelligent assembly line (3)

- Shaft manufacturing machine (6)

- BLDC motor stator winding machine (29)

- Armature winding line (144)

- stator winding line (221)

- Motor Components (130)

- Technical consulting and turn-key service (2)

Coil winding machine FAQ (5)

Motor Information (9)

Nide Profile (5)

Nide Certificates (14)

Nide factory show (2)

Nide product application (13)

Nide staff show (8)

News (30)

FAQ (29)

After-sales service (1)

Credit Report

Products Index

Motor Information

The difference between low inertia and high inertia of servo motors

What is the difference between low inertia and high inertia of servo motors?

Moment of inertia is equal to the radius of rotation multiplied by mass

Inertia is a measure of the inertia of a rigid body rotating around an axis. The moment of inertia is a physical quantity that characterizes the rotational inertia of a rigid body. It is related to the mass and quality of the rigid body relative to the distribution of the shaft. (Rigid body refers to an object that does not change under ideal conditions). When it is selected, it encounters motor inertia, which is also an important indicator of servo motor. It refers to the inertia of the servo motor rotor itself, which is very important for the acceleration and deceleration of the motor. If the inertia is not well matched, the motor's motion will be very unstable.

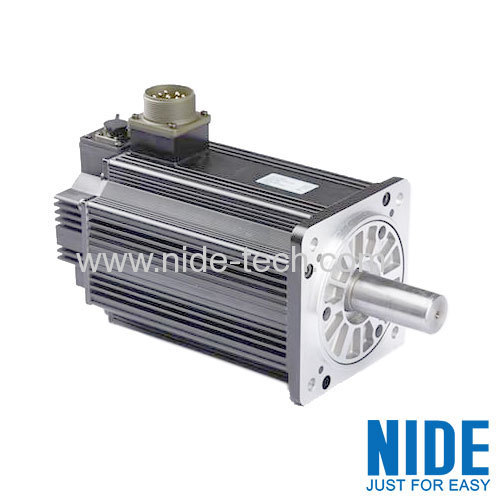

The low inertia means that the motor is relatively flat and the spindle inertia is small. When the motor is repeatedly operated with high frequency, the inertia is small and the heat is small. Therefore, low inertia motors are suitable for high frequency reciprocating motion. But the general torque is relatively small.

High inertia servo motors are relatively large and have large torques, which are suitable for high torque but not very fast reciprocating motion. Because of the high-speed motion to stop, the driver has to generate a large reverse drive voltage to stop this large inertia, and the heat is very large.

Generally speaking, the motor with small inertia has good braking performance, and the reaction of starting and accelerating stops is fast, and the high-speed reciprocating property is good. It is suitable for some light load and high-speed positioning occasions, such as some linear high-speed positioning mechanisms. Medium and large inertia motors are suitable for applications with high loads and high stability requirements, such as some circular motion mechanisms and some machine tool industries.

If the load is large or the acceleration characteristics are relatively large, and the motor with small inertia is selected, the motor shaft may be damaged too much. The choice should be based on the size of the load, the magnitude of the acceleration, etc., and the general selection manual has Related energy calculation formulas.

The servo motor driver responds to the servo motor. The optimum value is the ratio of the load inertia to the motor rotor inertia. The maximum can not exceed five times. The load can be made by the design of the mechanical transmission.

The ratio of inertia to motor rotor inertia is close to one or less. When the load inertia is really large and the mechanical design is impossible to make the ratio of the load inertia to the motor rotor inertia less than five times, a motor with a large rotor inertia of the motor, a so-called large inertia motor, can be used. To use a motor with a large inertia, the drive capacity should be larger to achieve a certain response.

Nide is a company devoted in the field of electric motors manufacturing, providing one-stop service for its customers.Make motor ,turn to NIDE.

Pre Page:

Motor classification and selection